Labor Risk Management Program: The Construction Risk Management Blueprint for Owners

What is the Labor Risk Management (LRM) Program?

The construction owners’ Labor Risk Management (LRM) Program is a full-service contractor pre-qualification and risk analytics system. It’s designed for owners to effectively evaluate contractors for workforce training and development (WFD) capability.

The objective is to:

- Pre-qualify and select contractors based on their WFD commitment, performance, activity and growth

- Facilitate more effective project execution by utilizing contractors with highly-qualified craft workers

- Facilitate more effective project labor planning

- Improve owner and contractor collaboration on establishing essential labor risk metrics

- Effectively measure workforce and productivity performance and improvement

Why Is Proper Construction Risk Management Important?

Owners have the most to lose financially when worker challenges are present. While contractors have the final responsibility to recruit, hire, train and retain workers, owners ultimately bear the cost. Active engagement will improve the owner’s bottom line and the industry overall. Taking action early in the project planning process enables the owner to control cost and influence what contractors do—just as it has for safety.

For decades, owners have consistently agreed that contractor prequalification should include WFD. In 1997, the Business Roundtable released a report stating,

“Owners should only do business with contractors who invest in training and maintain the skills of their workforce.”

This recommendation has been reaffirmed multiple times since by CURT and in August 2018 (RT-335) by the Construction Industry Institute.

How Does the LRM Program for Construction Risk Management Work?

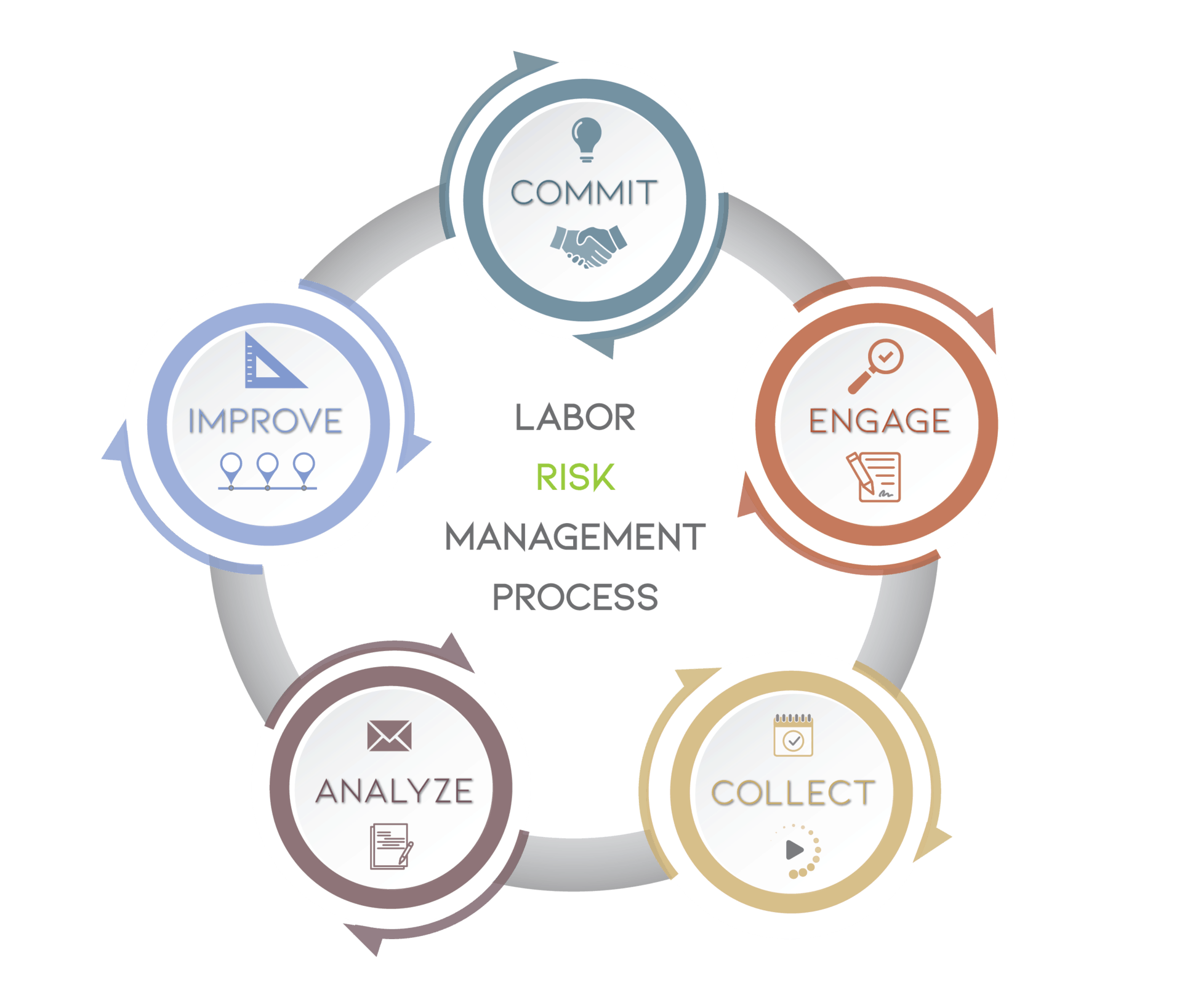

Step 1: Commit

The owner determines which contracts or projects are appropriately sized to deploy the LRM. The owner and/or the general contractor commits to the LRM Program for current and/or upcoming contracts or projects.

Step 2: Engage

The LRM Program is deployed during contractor bidding and selection, or a survey is initiated for current projects. WFD compliance is included in the contract language.

Step 3: Collect

Contractors are notified of the LRM decision and a 90-day compliance timeline. The contractor initiates the LRM Program by completing a CWDA assessment and submitting labor supply, productivity and safety data via the CLMA platform.

Step 4: Analyze

The LRM compliance is validated and the owner or general contractor is notified of initial compliance. Contractors are provided risk analytics information along with improvement opportunity reports.

Step 5: Improve

Results are continuously measured and benchmarked against workforce ROI expectations. LRM risk information and workforce improvement metrics are reported on a structured timeline.

Why Is The LRM Necessary for Construction Risk Management?

Chronic shortages of skilled labor are increasing costs and schedules and resulting in lower quality, more accidents and missed project objectives. Current forecasts indicate skilled labor shortages will increase with a growing economy and current industry age distributions.

Contractors, as employers, need to take the lead in developing new skilled resources for current and future projects. The recommended role for owners is to prequalify the contractors for all their projects based on WFD capability.

Applying the Safety Pre-Qualification Model to Labor Risk

Construction workplace safety is a primary concern and a cultural mindset for most companies, but consistent, effective workforce development and training have not been effectively addressed. The result is a construction industry significantly impacted by skilled labor availability challenges—not the availability of workers but of the skills required to execute projects.

In the past, when the owners declared safety to be a core value and business imperative, key contractor selection safety metrics were established, safety improvement innovation was unleashed, construction sites and projects become safer, and zero safety incidents became achievable. Owners understood the importance of safety for their own operations and most already had strong employee safety programs in place.

Safety Pays

What was needed was a standardized, institutionalized process for the industry as a whole and labor providers in particular. The recommendation to prequalify contractors for safety performance originated with the Business Roundtable (BRT), was based on the 1982 Construction Industry Cost Effectiveness study (CICE) and was predicated on demonstrated real cost savings in addition to avoiding accidents—e.g. “safety pays.”

- Avoided accidents reduced the direct cost of each accident including costs of emergency management, staffing, administration and investigations.

- Avoided accidents reduced the cost of crew work disruptions and productivity losses that occur when an accident happens

- Having fewer accidents reduced workers’ compensation insurance rates dramatically saving future $/hour costs

Training Means Better ROI

Similarly, when owners make workforce development a core value and a business imperative, the consistent development and deployment of effective workforce and training programs (and related metrics) will follow. CII research empirically demonstrates up to a $3.00 ROI for every dollar invested in training (RT-231). This will enable all stakeholders to lower costs and recoup their investment as it did for safety.

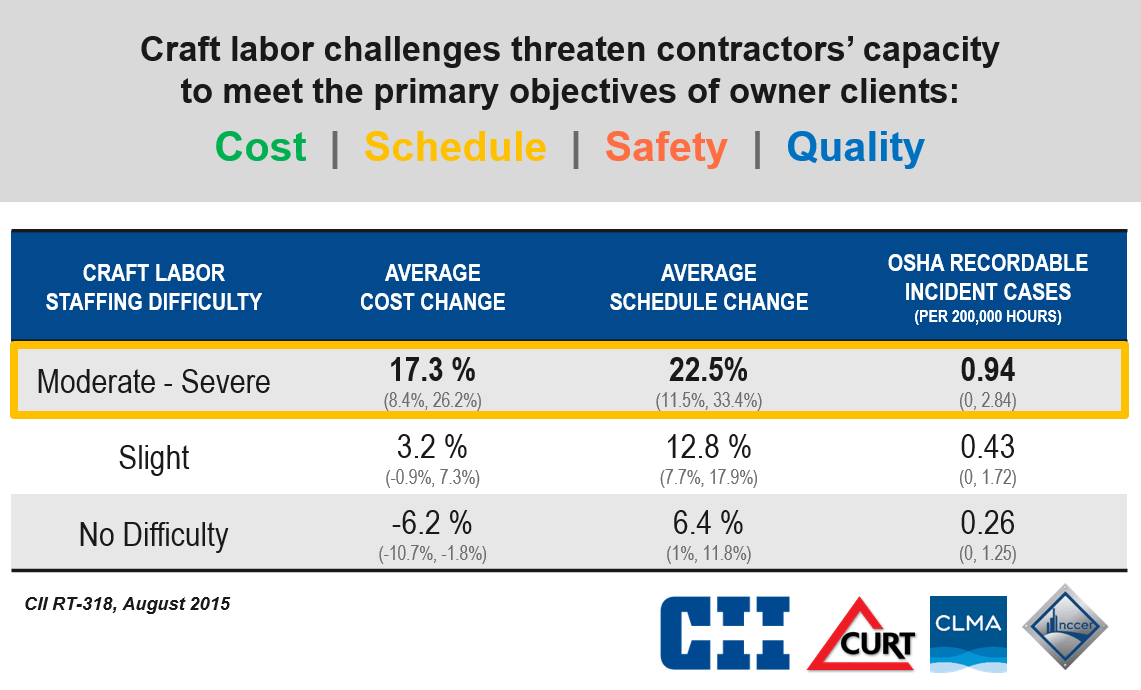

Skilled labor challenges threaten the ability to meet project objectives like safety, cost, schedule and quality. Recent research (RT-318) empirically demonstrated that labor shortages cause an increase in safety incidents, and other project objectives, directly proportional to the severity of the shortage experienced. Owners are in the unique position to lead, make workforce development a real priority, incent the right behavior and lessen/prevent avoidable project risk.

It’s time for action. See below to learn more and get started.

Daniel Groves

859.339.5071

dgroves@curt.org

Other Perspectives in the News…

2019Mar9 – CURT Rolls Out Program to Grade Contractors on Training

2019Jan31 – Is the skilled labor gap a threat to operational safety?

2019Jan30 – Why the workforce issue is as important as safety

2019Jan25 – The Owner’s Blueprint for Skilled Labor Risk Management

2019Jan9 – Recruiting Efforts Alone Won’t Solve Skilled Trade Shortage